Introduction :

Using solar energy to generate electricity has become a common thing in many countries and it is considered as characteristic of the Advanced countries but that technology encountered some problems to be more prevalent .

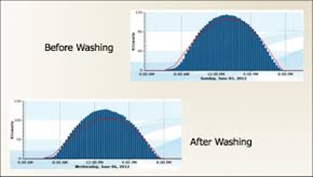

one of these problems is the accumulation of dust on the surfaces of cells responsible for generating electricity that reduces efficiency abroad By 30% to 35 which is a large percentage.

So the aim of this project is to design a robot to clean solar cells alone efficiently without using water.

Project stages :

1) idea stage:

We were thinking on how to make the solar cells cleaner work efficiently ,without water and adequate to the desert environment . this point passed several thoughts :

1st approach :

a robot that moves on horizontal surfaces (floor of houses) to clean it with the water, but this does not fit in clean cells because the cells demonstrate at an angle of 30 degree, therefore the movement had some difficulties to clean all The surfaces of solar cell.

2nd approach :

a small robot that moves on the surfaces of cells and uniformity and cleaning direction are controlled through four sensors placed at four different angles. also it does not use water in the cleaning process and depends on the movement of the brushes installed in the robot and it is efficient and high precision in The cleaning process. But needs to be accurate in design and manufacturing.

3rd approach :

a robot moving vertical and horizontal on solar cells set to clean the surface with high accuracy without the use of water in the cleaning process with simple movement style and it is very practical and can be controlled via mobile.

After studying the three types of these Robots, We found that the third one is an appropriate application robot and do not need more details and needs no water in the cleaning process.

2) implementation phase:

in this phase we started with robot design :

Software used :

SolidWorks

Machines Used:

-3D Printer

-Laser Cutter

Phase Steps:

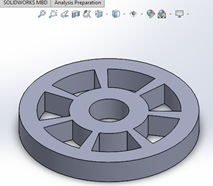

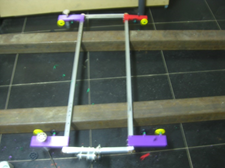

1) wheel design:

a set of wheels is responsible for horizontal And Vertical movement in the cleaning process is designed with solidworks and Printed using 3D Printer with 4 cm width and thickness of 6 mm.

And part of the leather is put on the edges of the Wheel to reduce friction by using Epoxy.

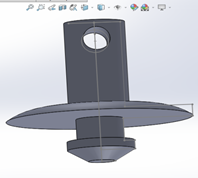

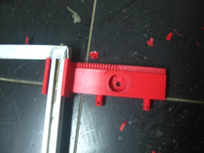

2) installing the wheels:

the part where you install the wheel with a mobile part along the vertical path.

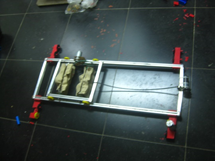

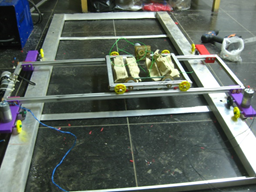

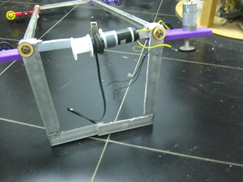

3) the robot body:

the part that holds the cleaning brushes and moving from top to bottom and vice versa and it is part of wood installed with part of metal.

.png)

4) cleaning part:

it consists of the rotor part which clean solar cells and a roll installed on hoop running by motor during cleaning.

A) roll: the roll was hand cut and installed on the body responsible for horizontal motion.

B)cleaning cloth : it is a soft cloth installed on the two rolls with dust adhesion qualities for cleaning.

C) install roll with steel column: it is an installation of steel column while keeping rotational motion of roll and it is divided into two Parts

1) permanent installation with one end: and the installation at the distance that allows free movement without interaction between the brushes , So that the distance between the two brushes is 10 cm which is its work space.

2) install the other end: the other end installation had some issues such as the installation process with the movement of the motor which caused nails on horizontal path to get loose , but started thinking in solving it by installation of 2 nut s for the brush in the right orientation for installation and connect the nail in the other end(steel column).

d) Motor for roll movement: it is the movement source for roll and its hoop is installed on the roll hoop and has the same diameter as it. the two rolls are also linked with each other and connected to the motor .

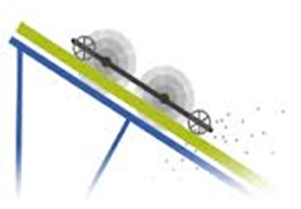

5)Vertical motion (the bottom up movement):

there is another motor to pull the robot upwards through a wire installed on the robot and there is pulley to facilitate movement in both directions (up and down) during the cleaning process.the robot moves down due to the weight because the cells installed at an angle of 30 degrees.

vertical Motion of robot (Winch Movement) Trial:

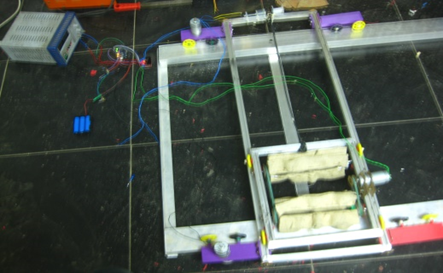

6) horizontal motion:

It is a movement of the robot on the body of the solar cells. consists of two rods

-2m length

-has 12 wheels (6 from the top and 6 from the bottom) and governs the process of motion control panel which derive their energy from a battery installed from the bottom of robot.

It consists of:

1) the road of a robot which is two steel column contain four roads in 6 mm width and 6 mm depth with an appropriate designed wheel thickness with thickness of the road.

2) install robot with the wheels to facilitate the movement above the surface of the solar cell.it consists of 2 places to install the motor and the other contains three places to install the wheels in the appropriate direction of motion.

The previous figure shows you where to install the motor with the wheel.

3)The motor : responsible for horizontal motion and there are two DC Motors : one in top and the other in the bottom to control the movement on the surface of the solar cell.

Specification of the motors :(12 volt, 0.8 amp, 300RPM)

Rated Voltage: 12Vdc

No Load Current: 140mA

No Load Speed: 300 r/min

Load Torque Current (With Load): 800mA

Load Torque Speed (With Load): 220 r/min

Torque: 1.3 Kgf.cm (0.13 N.m)

Output Power: 2.9 W

Stall Current: 3000mA

Motor Weight: 350~400 gm

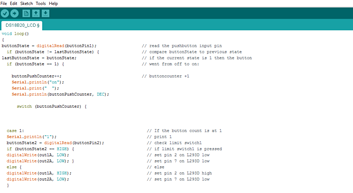

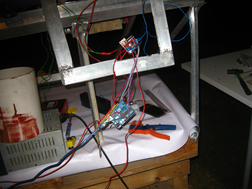

7) control part :

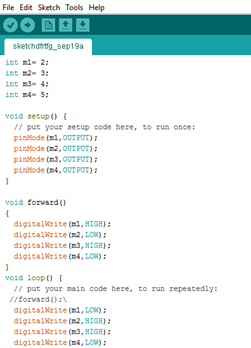

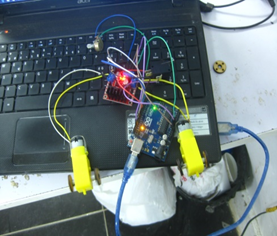

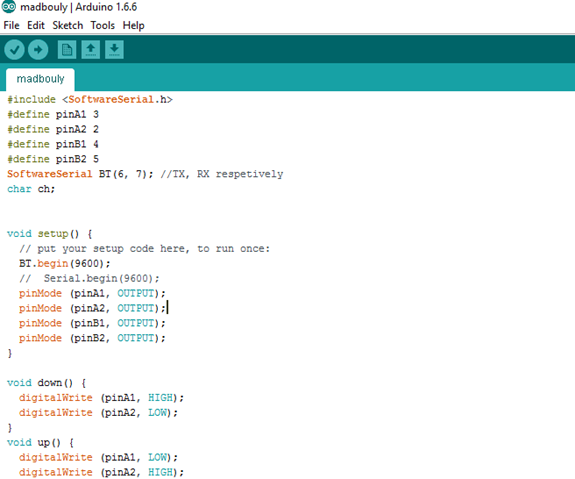

which controls the opening and closing of motor as well as horizontal and vertical robot movements as well as movement of brushes is made up of:1) two Arduinos,one for each two motors:

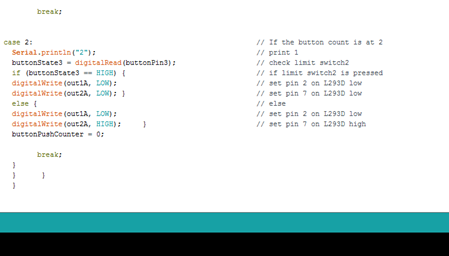

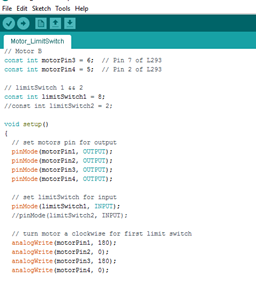

A. controlling the movement of the brushes and up motion so that whenever up motion is on , the brushes motion is stopped and when the robot reaches the highest point the brushes run with traffic down under the weight of the robot and uses limit switch with Arduino Uno and that code.

B. horizontal movement control : horizontal offset happens after the rise and fall of robot (cleaning cycle) to a distance of 30 cm which is about the width of the robot or Delay is done after a certain period by calculating the duration is for the robot for one cycle.

2) two Limit switch used in the process of closing and opening the circle.

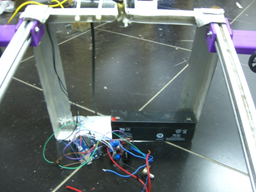

8) battery: power source for all parts

its specifications:

8) battery: power source for all parts

its specifications:-Rechargeable battery 12V 2.3 A hour.

- Dimensions 179x60x35 mm .

- Wight 970 ~ 860 gm.

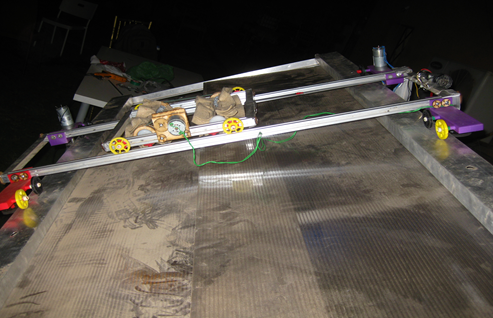

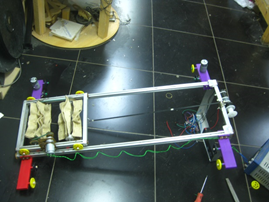

-Assembling robot parts

1)The car on which the brushes are installed by the wheels.

Make sure that the mater fits the torque to move the brushes

Car Holder:

Car Holder:

It is a square-shaped stales with a length of one meter and a width of 2 cm and contains a 6 mm width for the movement of the robot

And the rise and fall on the car and be installed on the body of cells at an angle of 30 degrees and the shape of the Arab after the installation of parts of the four wheels as follows

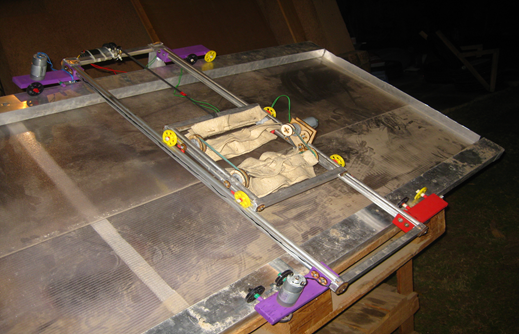

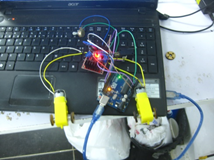

Assembling parts after adjusting the necessary parts for the robot movement and running the motor necessary for the horizontal movement along the solar cells

Using Mobile application:

Mobile is used to control robot movement and uses the Bluetooth module.

An animated video of the robot movement:

Flow chart:

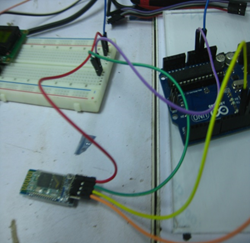

Control unit Consists of:

Control unit Consists of:

1) Arduino Uno

2) Two limit switch

3) Two resistance 2200 om

4) Two motor drive

So, they are divided into two control panels:

1) One of them controls the motor movement of feathers with the movement up and down through the winch at the beginning of the operation and the robot moves down with the motion of the mattresses when the control with the limit swatch installed from the bottom is closed motor brushes with the reverse motion movement mater to the (Winch) Cleaning and starting a new cycle.

Video shows that:

2)The horizontal movement of the robot on the surface of the solar cells and is controlled by the limit switch after the end of the first cycle of cleaning is pressed, which moves the robot movement horizontal.

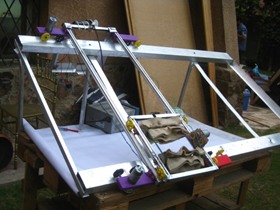

Solar cell:

We looked at the lack of solar cells in Fab Lab Egypt. A model that simulates the solar cells was done for the movement of the robot, the first prototype of the robot and the knowledge of the efficiency of the operation.

Control Box Holder:

Assembling the robot on the cells and activated to experiment at a 30 degree angle:

Control the movement of the robot:

The robot's motion is controlled by Mobile Application Components of the console:

1) Arduino Uno

2) Motor driver

3) Arduino Bluetooth Module

4) Mobil Application (Bluetooth RC)

Components Interfacing

Code:

Run the project: